Force sensor

Measuring forces precisely

Precise measurement, reliable control: force measurement sensors are at the heart of modern measurement and automation solutions. Whether in industry, research or quality assurance – they deliver exact measurement results even under demanding conditions. Discover high-performance sensor solutions that combine maximum accuracy, robustness and flexibility and make your applications measurably more efficient.

Find the right force sensor:

Measuring forces and keeping an eye on limits

Force transducers are often referred to as force measurement sensors – and for good reason. They contain a sensor element that detects the forces applied and converts them into an electrical signal. As these raw signals usually only have a very low signal strength, downstream amplification and filtering is required. For this reason, modern force measurement solutions often already integrate amplifier and signal processing components that convert the measured values into a signal that can be further processed. Careful calibration is essential to ensure permanently accurate and reproducible measurement results.

Typical measurement deviations range from around 0.05 to 2 percent of the full scale value (F.S.). In many applications, however, the focus is less on the exact force value and more on monitoring limit values. The decisive factor is whether a certain force is exceeded or not reached. This is precisely where force sensors show their strength, as they enable reliable and continuous monitoring.

This must be distinguished from load cells, which are often referred to together with force transducers, but differ in essential respects. They are characterized by higher measurement accuracy, deliver an unamplified, standardized output signal, and are designed for a defined nominal load, which is specified in a weight unit.

The right force sensor for every type of machine

The design of the sensors and their mechanical integration into the respective machine can be very flexible and application-specific. In contrast, the electrical integration into the machine control system follows established industry standards. Accordingly, the sensors are generally equipped with standard output signals, such as 0…10 V or 4…20 mA, which are also available redundantly on request. Digital interfaces such as CAN bus (CANopen) are also available. With the help of suitable control cabinet modules, the sensors can also be easily integrated into higher-level communication systems such as ProfiNet, ProfiBus DP, RS-485, Ethernet, Ethernet/IP, DeviceNet or EtherCAT.

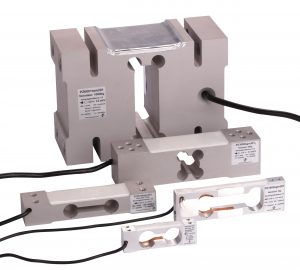

Different designs of force measurement sensors.

- Fork bearings often contain measuring axles which are also known as load measuring pins and replace a conventional pin with a measurable variant.

- The following are suitable for monitoring tensile forces in hoist ropes rope force sensors which are specially designed for this type of load.

- Shear force transducersalso known as shear rods, are particularly easy to retrofit as they can be mounted on one side with just two screws.

- If only little installation space is available load cells are a suitable solution thanks to their very compact design.

- For applications with extremely high forces ring force transducers are often used.

- In ceiling or support structures, for example in stage and event technology, on the other hand load measuring shackles which combine load suspension and force measurement in one component.

Force sensors

on hoists

A classic area of application for force transducers is lifting technology. This includes all systems with which loads are lifted and moved freely, such as cranes, aerial work platforms, lifting bridges or cable and chain hoists. If a lifting system is overloaded, this can cause damage to the system itself, to the transported load and, in extreme cases, serious injury. The use of force measurement sensors makes a significant contribution to avoiding or at least significantly minimizing such risks. Special sensor designs such as measuring shackles, tension measuring lugs and measuring axles – also known as load measuring pins or measuring pins – are often used in hoists.

Force sensors in industry and production

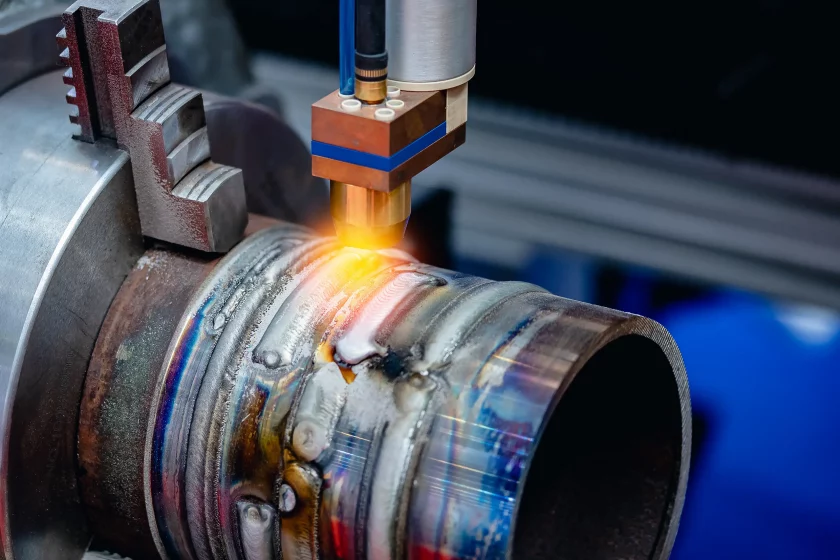

In modern industrial plants – especially in the chemical and process industries – force measurement sensors have become an integral part of many production processes. They ensure that production processes are stable and reproducible and that the manufactured products are of a consistently high quality. A typical example is joining technology, in which several components are permanently joined together. Whether riveting, welding, screwing, press-fitting or crimping: in all these processes, a precisely defined force is required to ensure a resilient connection and therefore a high-quality end product. Force measurement sensors precisely record and control the forces acting during the process.

They also play a decisive role in chemical production processes, for example when pressing dishwasher tabs, briquettes or tablets. Only if the pressing pressure is precisely maintained will all pressed pellets in a batch have the same strength and consistency. The measured values recorded in the process can be saved and archived, enabling complete process documentation. This means that production processes can be traced, checked and reliably reproduced at any time.

Versatile applications

The areas of application for force sensors are constantly expanding – especially against the backdrop of ever-increasing automation. In vehicles, for example, they enable control systems to detect seat occupancy or monitor the forces acting when closing windows and doors. In robotics, force sensors help to detect contact or reliably detect obstacles. They have also become indispensable in orthopaedic technology, for example as an integral component of active prostheses.

Primosensor meets these requirements with innovative know-how and develops tailor-made solutions – either independently or in close cooperation with its customers. The aim is to realize reliable force measurements exactly where they are needed.

Are you looking for the right force transducer? We would be happy to help you choose from our portfolio or advise you on individually developed solutions.

Force transducers and functional safety

Primosafe force transducer

A component’s functional safety is a vital product feature in the construction of machines and plants. It requires extensive analysis and documentation, as early as during the development and construction stage. This allows us to determine the probability of failure, which is then categorised in accordance with the safety standards EN 13849 and EN 61508.

A component’s probability of failure and other indicators derived from that probability are called safety data.

Safety data sheets in accordance with safety standards EN 13849 (PL) or EN 61508 (SIL) are available for all our force transducers. To improve safety, our force transducers are also available in a redundant design.

Learn more: