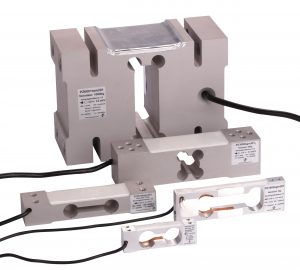

Force transducer & force sensor

Precise force measurement with high-quality force sensors

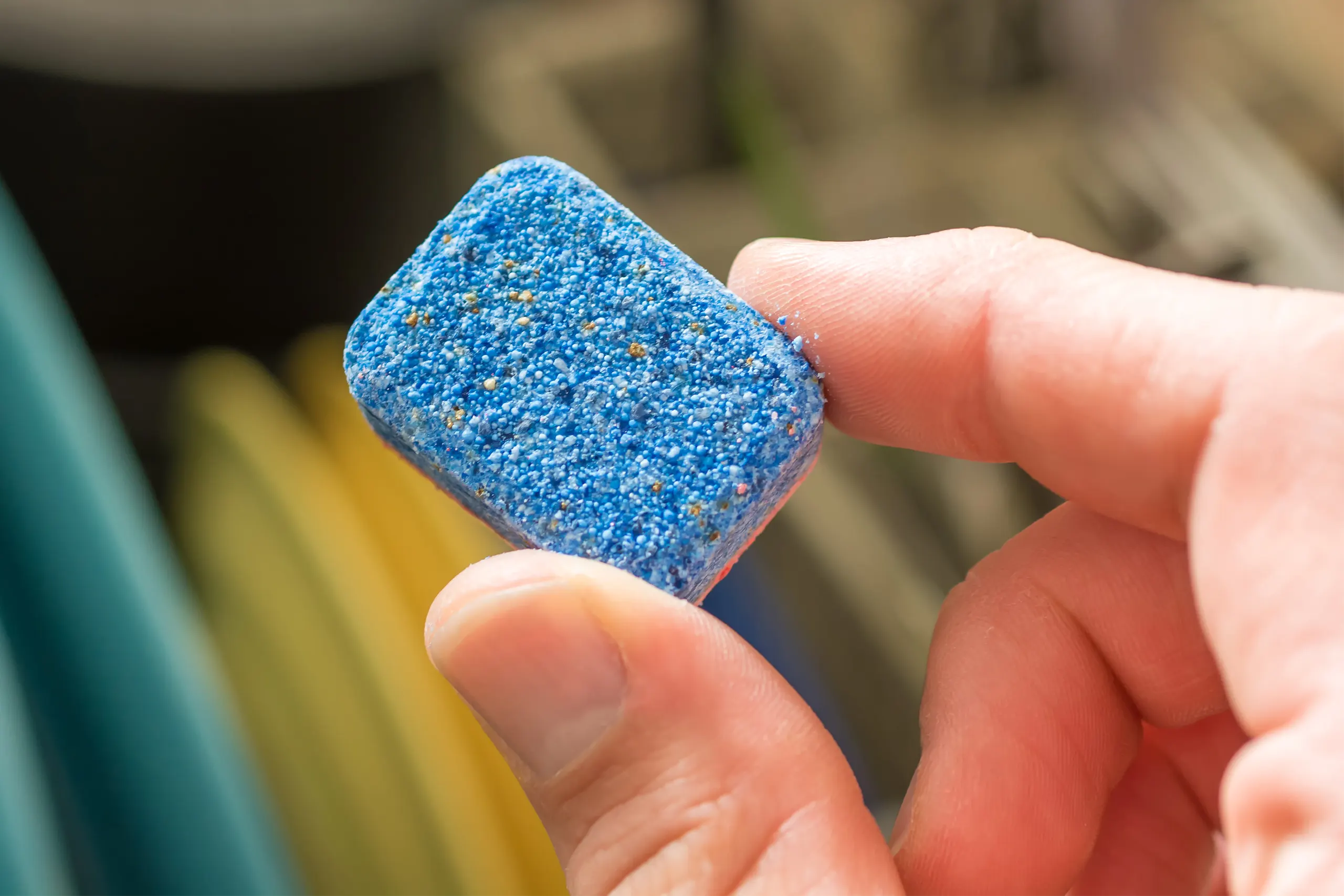

Force sensors, also known as force transducers, detect whether a car seat is occupied or empty, prevent cranes from carrying loads that are too heavy, ensure a uniform material density in dishwasher tabs or the same pressure cycle on the component to be formed in presses. They convert mechanical forces into measurable electrical signals.

The types of force transducers or force sensors are as diverse as their areas of application.

However, the basic operating principle of sensors always remains similar.

Learn more about our products:

Are you looking for the right product for your application?

Measuring and verifying forces

It is no coincidence that force transducers are also widely referred to as force sensors. Because they consist of a sensor that measures forces and converts them into an electrical signal. The output signals from force sensors are usually very small and need to be amplified and filtered. Modern force measurement systems therefore often include amplifiers and signal processing units that convert the signal into a usable format. Calibration is also an essential step to ensure that the measurements are precise and reliable.

Deviations are typically in the range of 0.05 to 2 percent. However, it is often not about the exact amount of force acting on the force sensor – but about ensuring that it does not exceed or fall below a specified value. In such cases, force sensors play a central role, as they provide precise data and thus enable reliable monitoring.

The situation is different with load cells, which are often mentioned in the same breath as force transducers: They differ from force sensors primarily in their significantly higher accuracy, an unamplified standardized output signal and the specification of the nominal load in a unit of weight.

The right sensor for every machine type

There are different types of force transducers.

- For fork bearings, so called load pins are suitable as a “smart” substitute for an ordinary pin.

- For hoisting ropes, rope load sensors or “clamp-on” sensors are the right choice. Die Scherkraftaufnehmer oder auch Scherstäbe lassen sich für ein schnelles Nachrüsten einseitig mit zwei Schrauben montieren.

- Load button force transducers convince with their particularly compact design.

- Ring force transducers are a good choice for measuring very large forces.

- Load measuring shackles are used in ceiling or support structures in the field of stage technology.

Force transducers and force sensors

for lifting devices

A typical application area for force transducers is lifting equipment, i.e., all devices that lift and move loads while suspended freely. This includes cranes, lifting platforms, lifting bridges or cable winches. Overloading a lifting device can lead to damage to the lifting mechanism, the loads being moved, and in the worst case, personal injury. Force sensors prevent this or significantly reduce these dangers. Typical force sensors used in lifting equipment are measuring shackles, tension measuring lugs and measuring shafts, also called load measuring bolts or measuring bolts.

Force transducers in industry and chemistry

Force transducers are now indispensable in numerous manufacturing processes. There, they ensure that the manufactured products have a consistently high quality and that the processes run smoothly. One example is joining technology, which involves permanently connecting two or more components together. Whenever rivets, welds, screws, press fits or crimp connections hold parts together, a predefined pressure is needed to guarantee a stable connection and thus a high-quality end product. Force sensors monitor and control the pressure exerted on the individual parts during the manufacturing process. This also plays an important role in other manufacturing processes, such as in the chemical industry when pressing dishwasher tablets, briquettes or tablets, so that all pressed products of a type ultimately have the same consistency.

The measured data can be saved and archived to document the process. This makes it easy to control and reproduce them.

Versatile applications

The application possibilities for force sensors are constantly growing – especially in an increasingly automated world. They allow control systems in motor vehicles to recognize, for example, the occupancy of the seats or the closing forces of windows and doors. Robots use force sensors to detect touches or obstacles. Active prostheses in orthopedics also have integrated force sensors.

Primosensor addresses these challenges and develops new, optimized solutions for or together with customers that enable force measurement wherever it is needed.

Are you also looking for the ideal force absorber? We will gladly search our product range for the right force transducer or advise you on individual solutions.

Force transducers and functional safety

Primosafe force transducer

A component’s functional safety is a vital product feature in the construction of machines and plants. It requires extensive analysis and documentation, as early as during the development and construction stage. This allows us to determine the probability of failure, which is then categorised in accordance with the safety standards EN 13849 and EN 61508.

A component’s probability of failure and other indicators derived from that probability are called safety data.

Safety data sheets in accordance with safety standards EN 13849 (PL) or EN 61508 (SIL) are available for all our force transducers. To improve safety, our force transducers are also available in a redundant design.

Learn more: