Strain gages (DMS)

for precise measurements

Strain gages are an indispensable part of sensors in modern measurement technology. They precisely convert mechanical strain into electrical signals and are used in force sensors, pressure sensors and load cells. Whether for strain gauge pressure measurement or for monitoring mechanical loads – our high-quality strain gauge sensors offer reliable results and are ideal for industrial applications.

Table of contents

The majority of force transducers used worldwide are manufactured with bonded strain gauges. However, we always check whether customer requirements can be better fulfilled by sensors using thin-film or thick-film technology.

Introduction to strain gauges

What are strain gauges?

Strain gauges measure mechanical strain. They consist of a conductive structure on a carrier material. When the material to which they are bonded is stressed, their electrical resistance changes in proportion to the strain. This change is converted into a precise electrical signal that reflects the deformation of the material. Strain gages are used in technology, research and industry to analyze material stresses and test load limits.

Significance in measurement technology.

Strain gauges are indispensable for the precise detection of mechanical loads in industry. They enable accurate measurements in applications such as force sensors, pressure sensors and load cells. Thanks to their reliability and versatility, strain gages are used in areas such as mechanical engineering, the automotive industry and medical technology. They help to ensure safety, optimize processes and monitor load limits in real time.

The birth of the DMS

The strain gauge was born in 1938. Force sensors have been built with them ever since, as they enable a huge variety of geometries. Using strain gauges, high-precision force sensors (load cells) can be produced.

Functional principle of strain gauges

How does a strain gauge work?

The functionality of a strain gauge (also known colloquially as a strain gauge) is based on the change in electrical resistance when deformed. The strain gauge consists of a sensitive resistance material that is attached to a carrier. If the material is stretched or compressed, the strip adapts, causing a measurable change in resistance. This is precisely recorded via a Wheatstone bridge and translated into an electrical signal. The signal provides direct information about the magnitude of the mechanical stress.

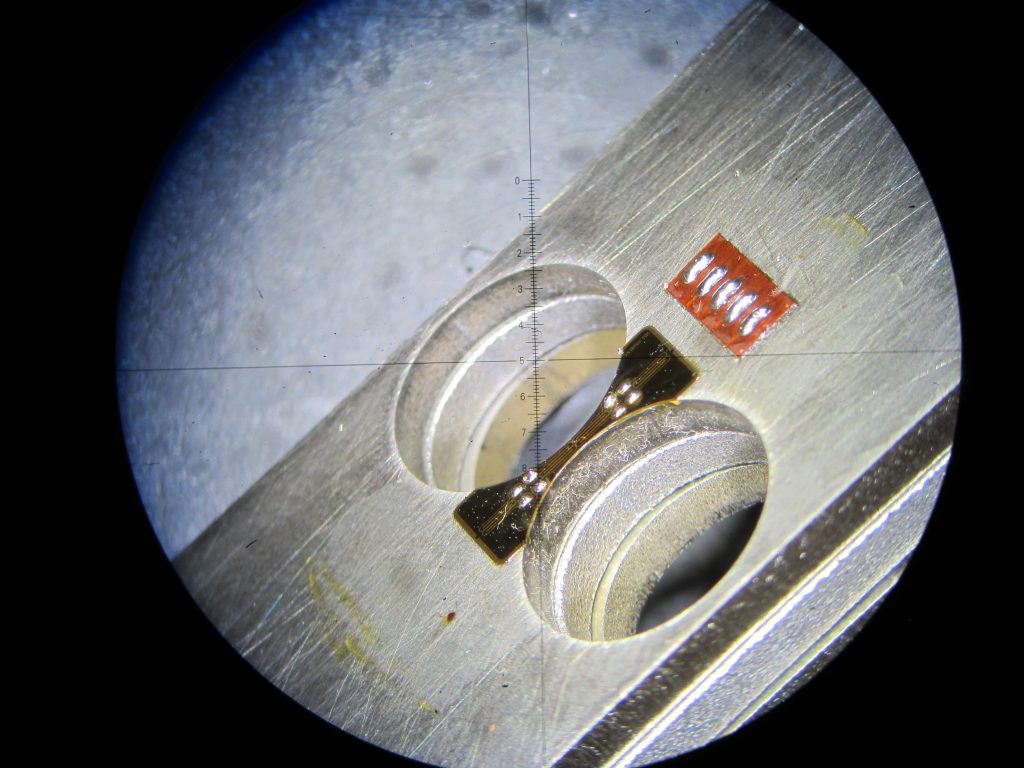

Meander-shaped resistors on a carrier foil

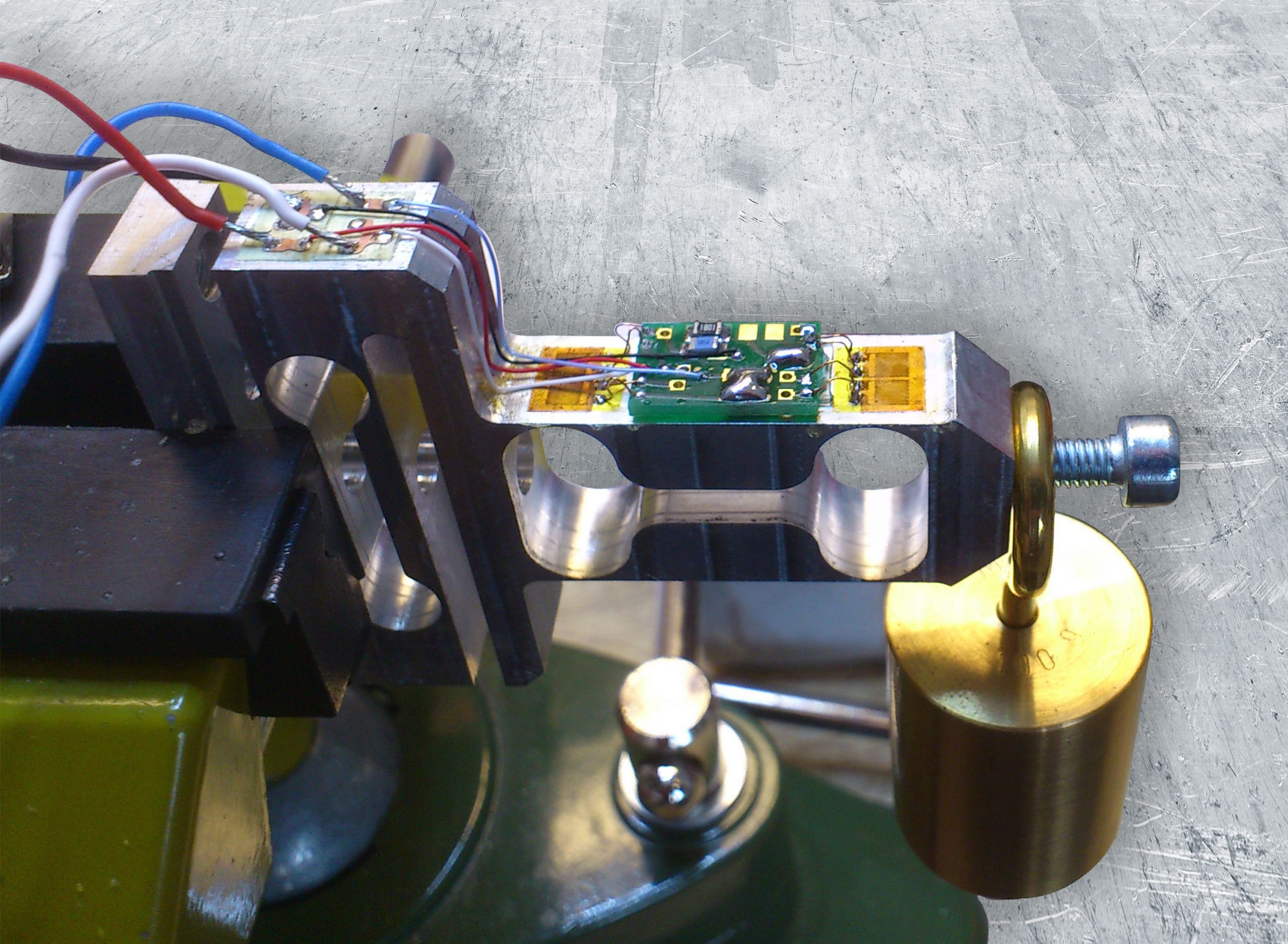

Force sensors are usually measurement springs which elastically deform when load is applied. Strain gauges are glued to their strain and compression zones. Wired to a Wheatstone bridge, they produce a load-proportional, electrical output signal.

The strain gauges are meander-shaped resistors on a carrier film, which makes them extremely versatile. They can be easily adjusted to any measurement spring material, such as steels or aluminium. As both flat and spherical surfaces can be used to detect strains, the number of possible forms for measurement springs is almost unlimited.

Advantages and challenges

when using strain gauges

Advantages of DMS

Strain gages offer numerous advantages. Their high precision enables exact measurements of forces, pressure and strain, even in demanding applications. Thanks to robust materials and careful processing, they are characterized by a long service life, even under high loads. Their flexibility of use makes them ideal for applications in force sensors, pressure sensors, load cells and structural tests.

Challenges in use

There are several challenges when using strain gages. Temperature influences can falsify measurements, which is why temperature compensation is often necessary. The long-term stability of strain gages depends on the quality of the adhesive and the material. Mechanical overloads can damage the strip or impair its precision. In addition, installation requires great care, as even small installation errors can distort the measurement results. Regular calibration is also necessary to ensure accuracy.

Precision redefined

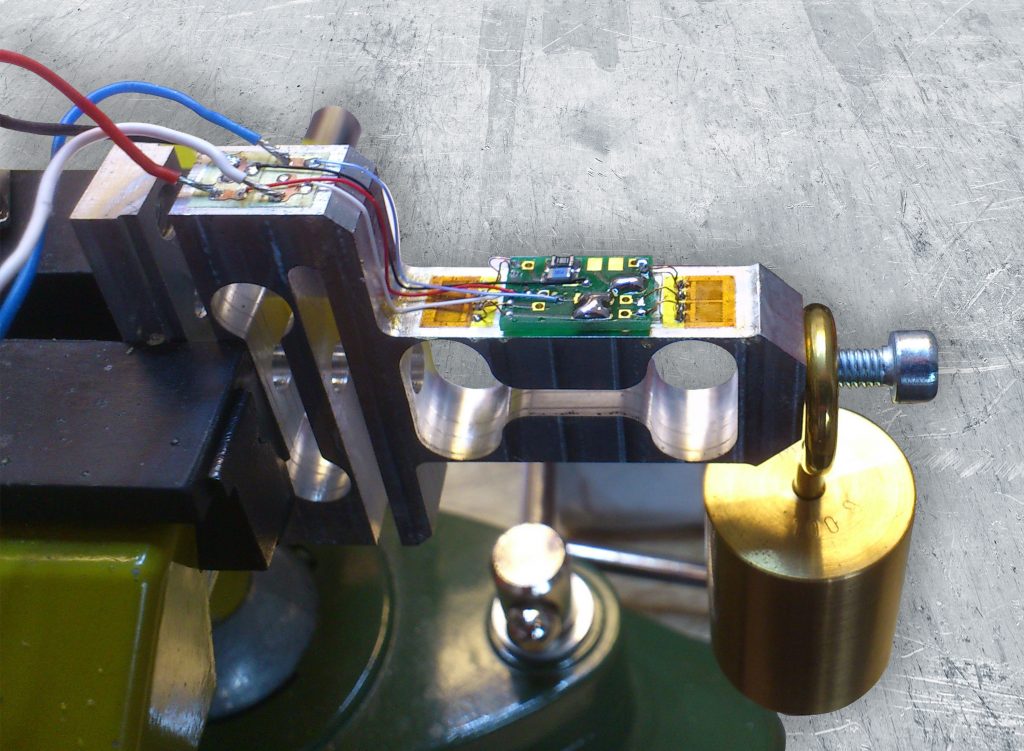

Our thin-film strain gauges for multi-component sensors

Significance for multi-component sensor technology

In high-precision multi-component sensor technology, absolute reliability and accuracy are essential – even under demanding conditions. Primosensor therefore relies on thin-film strain gauges developed specifically for this purpose. We have optimized these specifically for use in our 6-axis force/torque sensors.

Why new thin-film strain gauges for multi-component sensors?

In contrast to conventional semiconductor strain gauges, which require complex temperature compensation and are more susceptible to external influences, thin-film strain gauges offer numerous technical and economic advantages. Our thin-film strain gages are tailored to the requirements of 6-axis force/torque sensors. The precise detection of complex forces and moments in three spatial directions is not only possible, but measurably better.

The advantages at a glance

Highest temperature stability

Thin-film strain gages exhibit excellent thermal behavior – without any complex compensation circuits.Long-term stability and robustness

Thanks to their metallic structure and direct application to the sensor body, they are particularly resistant to ageing and environmental influences.Excellent linearity and repeatability

Ideal for precise measurements in all six degrees of freedom – even with dynamic load changes.Compact design enables higher integration density

Perfect for compact, highly integrated multi-component sensor solutions.High measurement resolution with low drift

For reliable data – even with long periods of continuous use and changing ambient conditions.

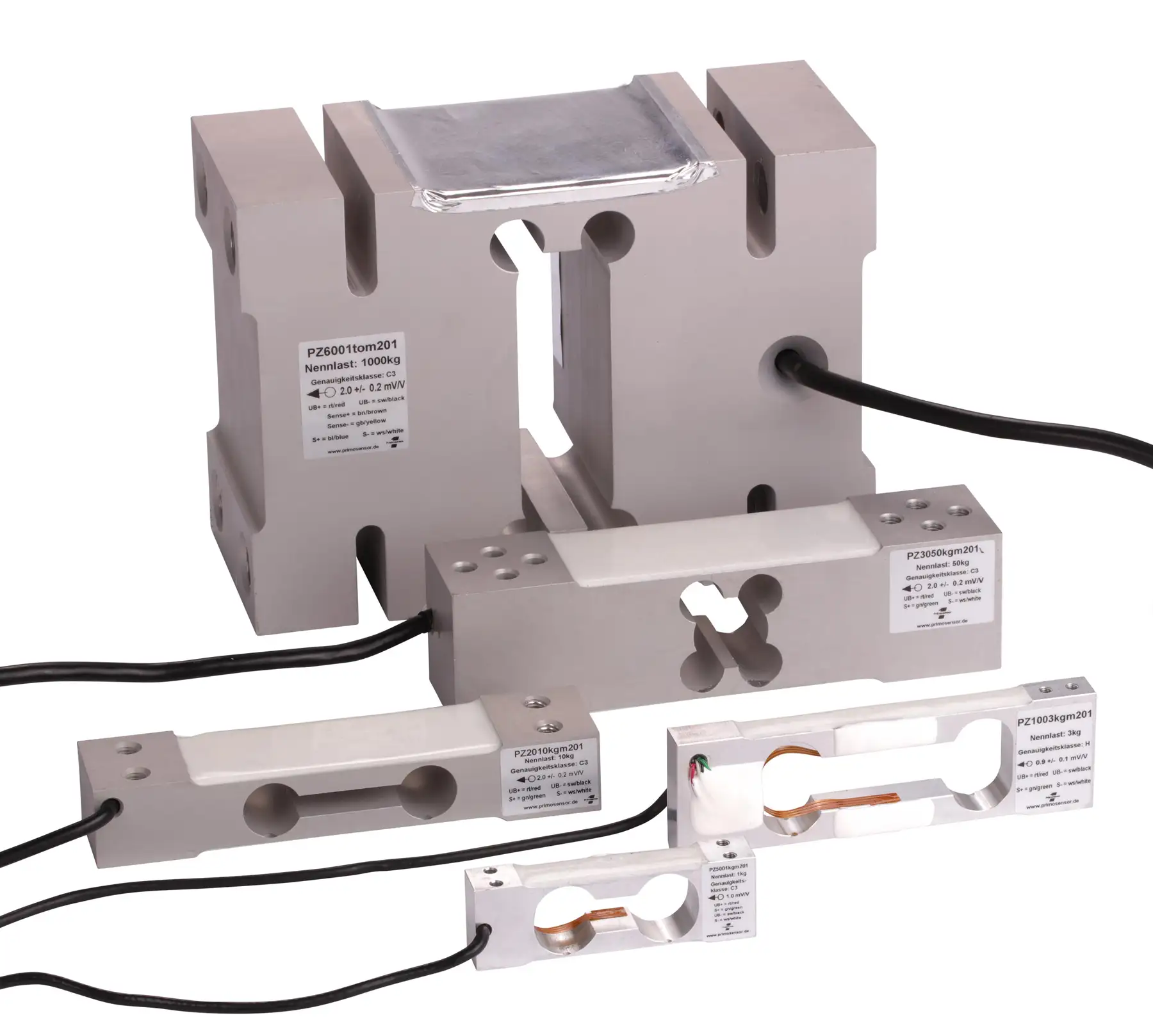

We carry a wide range of products with bonded strain gauges

(Bonded) Strain Gauges

Bonded strain gauges are the most common design and are characterized by their easy handling and high measuring accuracy. They are bonded directly to the surface to be measured and provide precise, reliable results. This design is ideal for applications in force sensors, pressure sensors, load cells and structural tests.

Vapor-deposited strain gauges

Vapor-deposited strain gauges are applied directly to the surface as wafer-thin layers. This design is extremely robust, resistant to high temperatures and delivers reliable results, even under demanding conditions. It is frequently used in research, aviation, high-performance and industrial applications.

Other types of DMS

Molded-in or integrated strain gages are particularly stable and protected from environmental influences, making them ideal for load cells and robust industrial applications. Wire strain gages, an older technology, use wires as resistance elements. They are simpler and less precise, but are still used in specific niche applications. Semiconductor strain gages offer exceptionally high sensitivity, but are temperature sensitive and therefore mainly suitable for research and precision measurements. Thin-film strain gages are applied to metal substrates, are extremely robust and ideal for high-load sensors. Thick-film strain gageswhere resistive material is printed on ceramic substrates, are characterized by their durability and versatility, especially in industrial measurement systems.

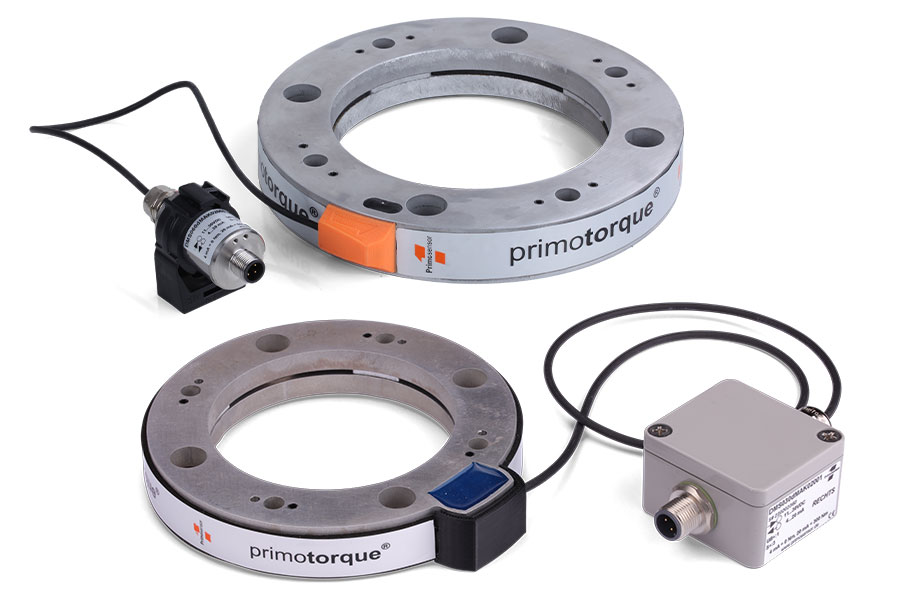

Applications of DMS

Precision and versatility for mechanical engineering to aviation

Strain gages – also known colloquially as strain gauges – are widely used in industries such as mechanical engineering, the automotive industry, aviation and construction. They monitor loads, ensure quality control and optimize mechanical systems. Their ability to precisely measure mechanical strain makes them indispensable for the development of safe and efficient products and for checking material stresses. Thanks to their flexibility, strain gauges can be used almost endlessly – from flat to spherical surfaces, with sensors for nominal loads ranging from a few grams to hundreds of tons. With optimum adjustment, they achieve accuracies in the ppm range.

Force measurement

(e.g. strain gauge load cell)

In force measurement, strain gauges are integrated into load cells to precisely record mechanical forces. They enable the monitoring of compressive, tensile or shear forces and are used in test benches, machines and production lines. Thanks to their precision, strain gauge load cells are ideal for industrial automation and for monitoring load limits in sensitive applications.

Pressure measurement

(e.g. strain gauge pressure sensor)

Strain gauge pressure sensors use strain gauges to measure pressure changes caused by mechanical deformation of a diaphragm. These signals are converted into precise measured values. Typical areas of application are hydraulic systems, pneumatics, environmental measurements and industrial processes where pressure has to be monitored or regulated. Strain gauge pressure sensors offer high accuracy and reliability.

Further applications: Load cells, structural tests, etc.

Strain gauges are also used in load cells to enable precise weight measurements, e.g. in platform scales or conveyor systems. In structural tests, they measure material loads and deformations, for example in bridges or airplanes, and contribute to safety. They are also used in robotics, medical technology and research, where precise measurements are crucial.

Maximum accuracy in the ppm range

Despite nominal loads ranging from a few grams to several hundred tons, accuracies in the ppm range can be achieved with optimum coordination of all components. However, most industrial applications require accuracy in range of 0.2….2% which allows us to significantly reduce production effort.

Typical designs of force sensors are measuring axes – also known as load measuring pins -, tension force sensors, S-types or shear and bending rods, load cells as compression force transducers in round or cylindrical design and platform load cells. All standard designs are available in our online shop.

Telephone advice on +49 6071 63467 50.

Frequently asked questions

What is a strain gauge and how does it work?

A strain gauge is a measuring device for detecting stretching and compressing deformations and changes its electrical resistance even with small deformations.