Load cells and weighing modules

Load cells play an important role in our everyday lives. They are part of bathroom scales or the scales in the fruit and vegetable department in your local supermarket. The load cell is also indispensable in industry. Load cells help monitoring stock and material flow in logistics and production and make sure operations run smoothly.

Large selection of load cells and weigh modules

High-load weighing modules

(incl. high-load load cells)

- For silo and container weighing

- For use in truck scales indoors and outdoors

- from 5,000 kg to 100,000 kg

Single point load cells

- Platform scales with only one load cell positioned centrally under the platform

- from 150 g to 2,000 kg

Bending and shear beam load cells and weighing modules

- Frequently used in the industry

- from 300 kg to 10,000 kg

Tension / compression load cell

(S-types)

- Standard in the industry

- High accuracy

- Measurement of tensile and compressive forces

- from 100 kg to 10,000 kg

Compression load cells

- Compact design and dimensions

- Use even under the most difficult environmental conditions

- from 150 kg to 100,000 kg

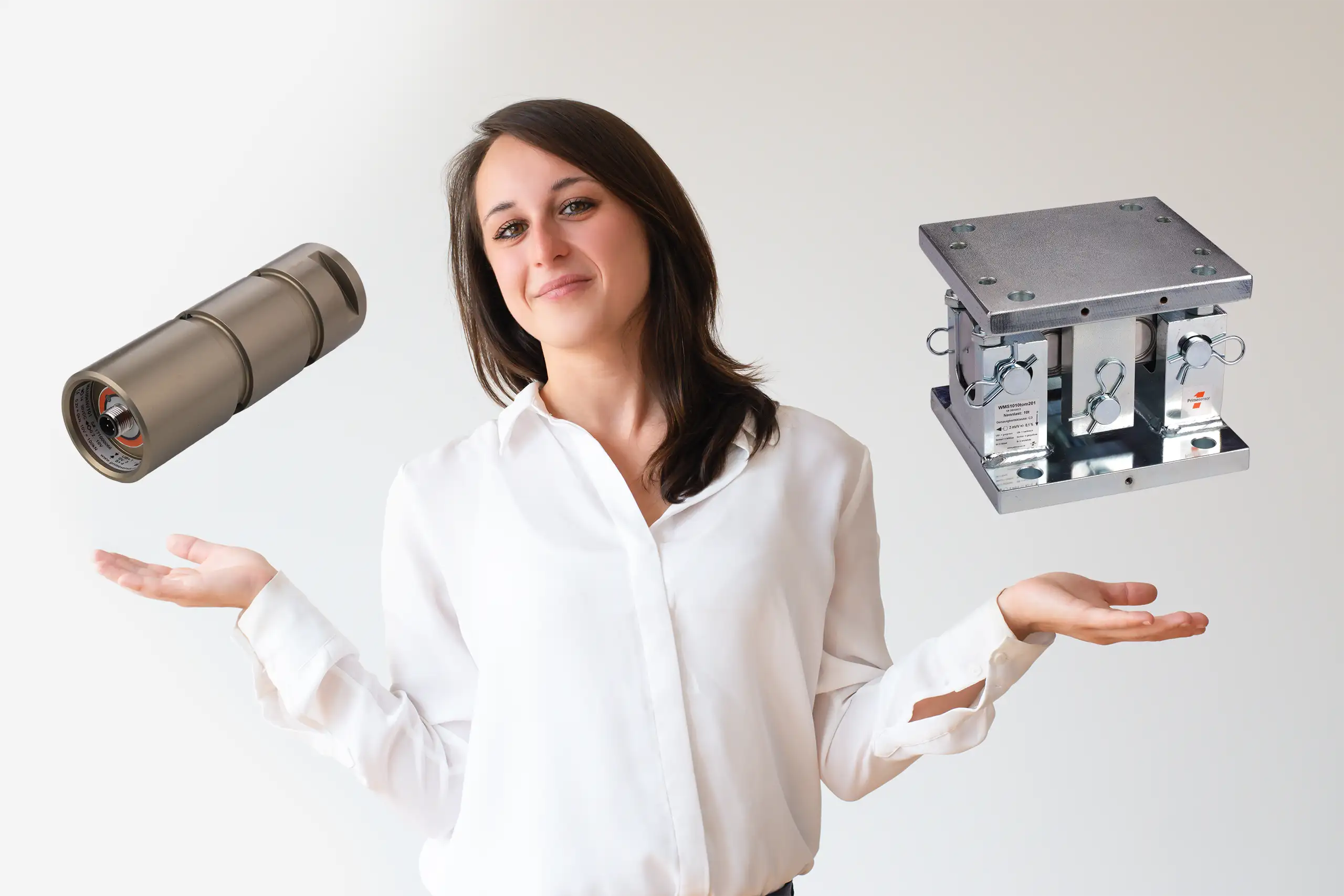

Force transducer versus load cell

The load cell also differs from other force transducers in other respects: A load cell is designed to detect weight forces, i.e. forces that act in the direction of the centre of the earth via gravity; other forces, which can of course act in all possible directions, are usually measured with a force transducer. Load cells tend to be designed for static applications; force transducers tend to be designed for dynamic to highly dynamic applications with many load changes. Unlike in the application of force transducers, high and very high precision is much more important in weighing technology. We are talking about deviations between 0.01 and 0.05 per cent here.

However, load cells and force transducers share a number of technical features and application fields.

How do load cells work?

Load cells are considered force transducers because they are very similar in structure and functioning. Just like most force transducers, load cells consist of a spring body. Strain gauges in form of a Wheatstone bridge are attached onto the spring body. These strain gauges detect when the spring body is stretched or compressed and render this information into a change of the electrical resistance. This change allows us to determine the weight, tension, or compression forces applied to the spring body.

Built-in temperature compensation

To guarantee correct measurement results even at a wide range of temperatures, the load cell has built-in temperature compensation. This is especially important for load cells used in environments that are prone to changing weather conditions or temperatures, such as trucks or outdoor scales for silos.

Industrial and technological application of weighing modules and load cells

Load cells are used in many different industries and technologies, such as process engineering, machine, vessel, or plant construction, food industry, medical technology, and agriculture. Many applications require precise measuring and documentation of weight forces. In some cases, those are even required by law. Filling systems in the food industry fulfil legal standards only when they use load cells to make sure that cans, bottles, or bags have the same net weight.

Load cells are also used to determine material stock and consumption as well as the quality of intermediate and final products. There are many different types of load cells for many different nominal loads – from 100 grams to 1,000 tons.

This way, they can be used both in precision scales to measure to an accuracy of 0.01 grams and silo and vessel scales, platform scales, filling scales, or truck weighing machines, where several tons of weight are applied.

Easy installation and use

Only correctly installed and used sensors can deliver precise measurements and live up to their expected lifespan. To support you with installation and usage of our load cells, we have developed mounting tools and installation kits which you can order on our website, too. Still unsure which components are the right one for you? Please don’t hesitate to contact us – we are happy to help.

Looking for the perfect load cell or weighing module?

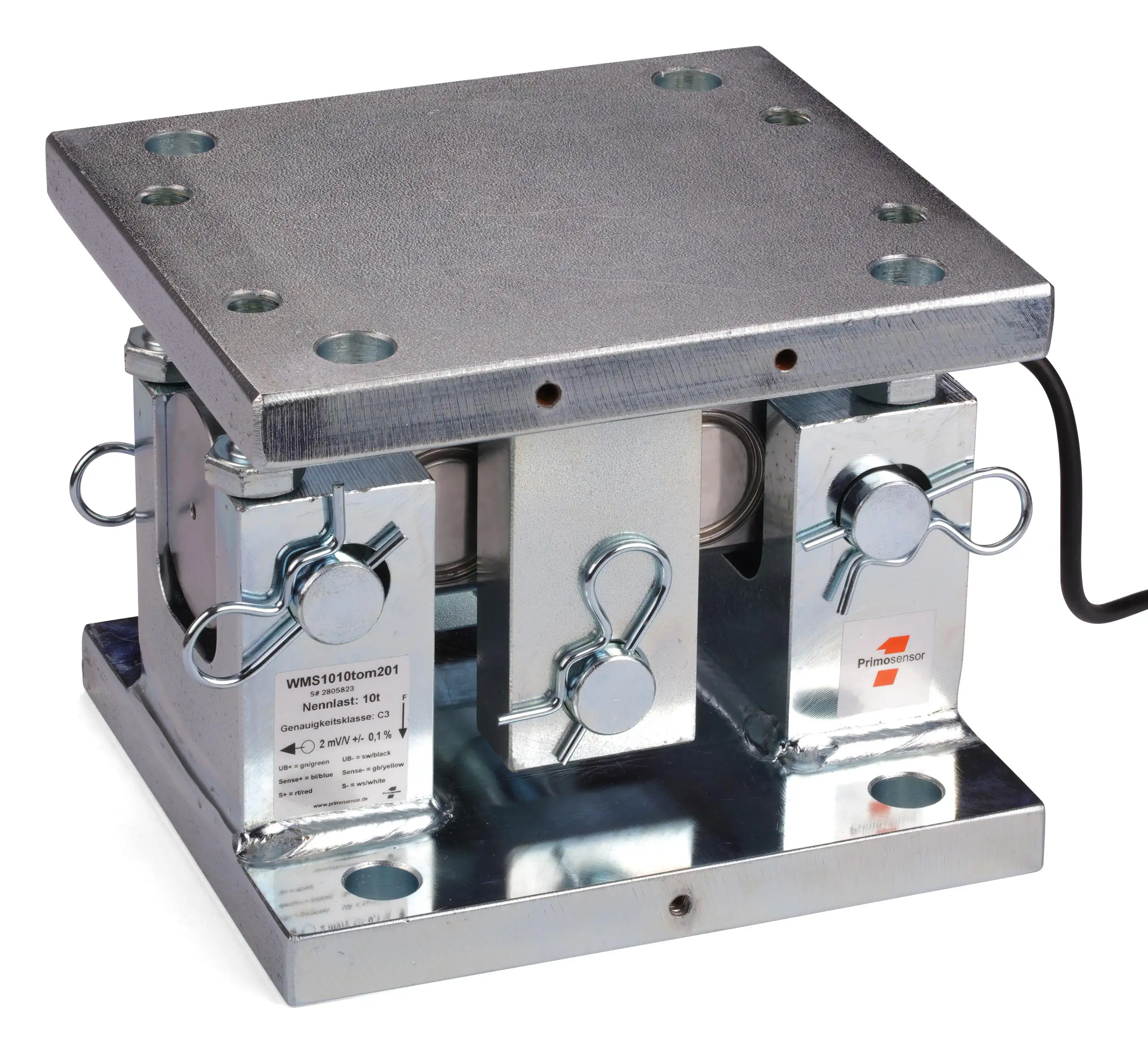

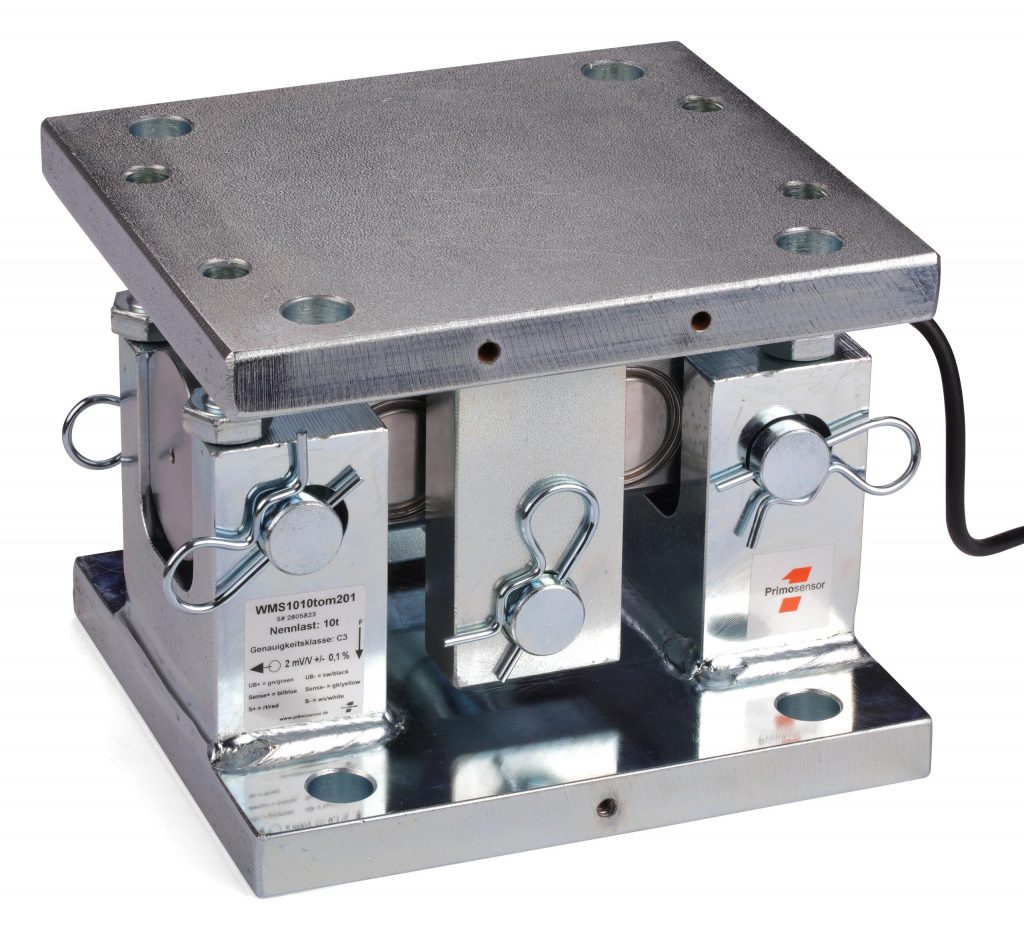

High capacity weighing module

- For silo and container weighing

- For use in truck scales indoors and outdoors

- from 5,000 kg to 100,000 kg

- Accuracy <0,017 % F.S.

- Consisting of load cell and installation kit

The WMS1 weighing module, consisting of a stainless steel double shear beam load cell with a high degree of protection (IP 68) and a very robust installation kit, has been specially developed for the precise weighing of medium to large silos and containers as well as for use in truck scales indoors and outdoors. The weighing module is available with nominal loads from 5 t to 100 t.

Downloads | Data sheet & STEP files

Tension / compression load cell

- Standard in the industry

- High accuracy

- Measurement of tensile and compressive forces

- from 100 kg to 10,000 kg

- Accuracy <0,020 % F.S.

S-Type load cells are standard for industrial applications. They are used for measurement of tension and/or compression. Force indroduction happens via swivel heads. The advantages of S-Type load cells are their high level of accuracy, the ability to measure tensile and compressive forces, simple installation and the rotationally symmetrical design.

Downloads | Data sheet & STEP files

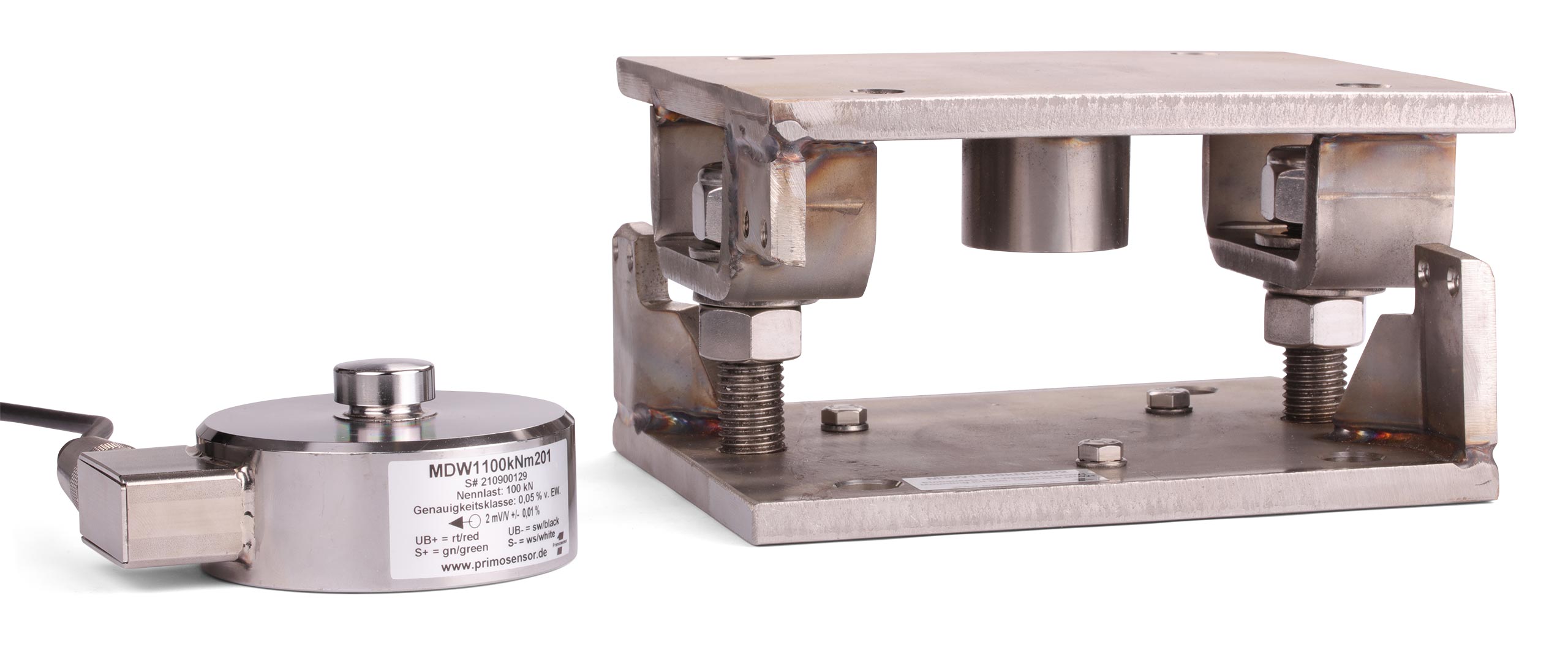

Compression load cell

- Compact design and dimensions

- Use even under the most difficult environmental conditions

- from 150 kg to 100,000 kg

- Accuracy <0,03 % F.S.

Rotationally symmetrical compression load cells impress with their compact design and dimensions even with very high loads or forces. Due to its robustness combined with very good accuracy, the MDW load cell is suitable for a wide range of classic weighing applications.

Downloads | Data sheet & STEP files

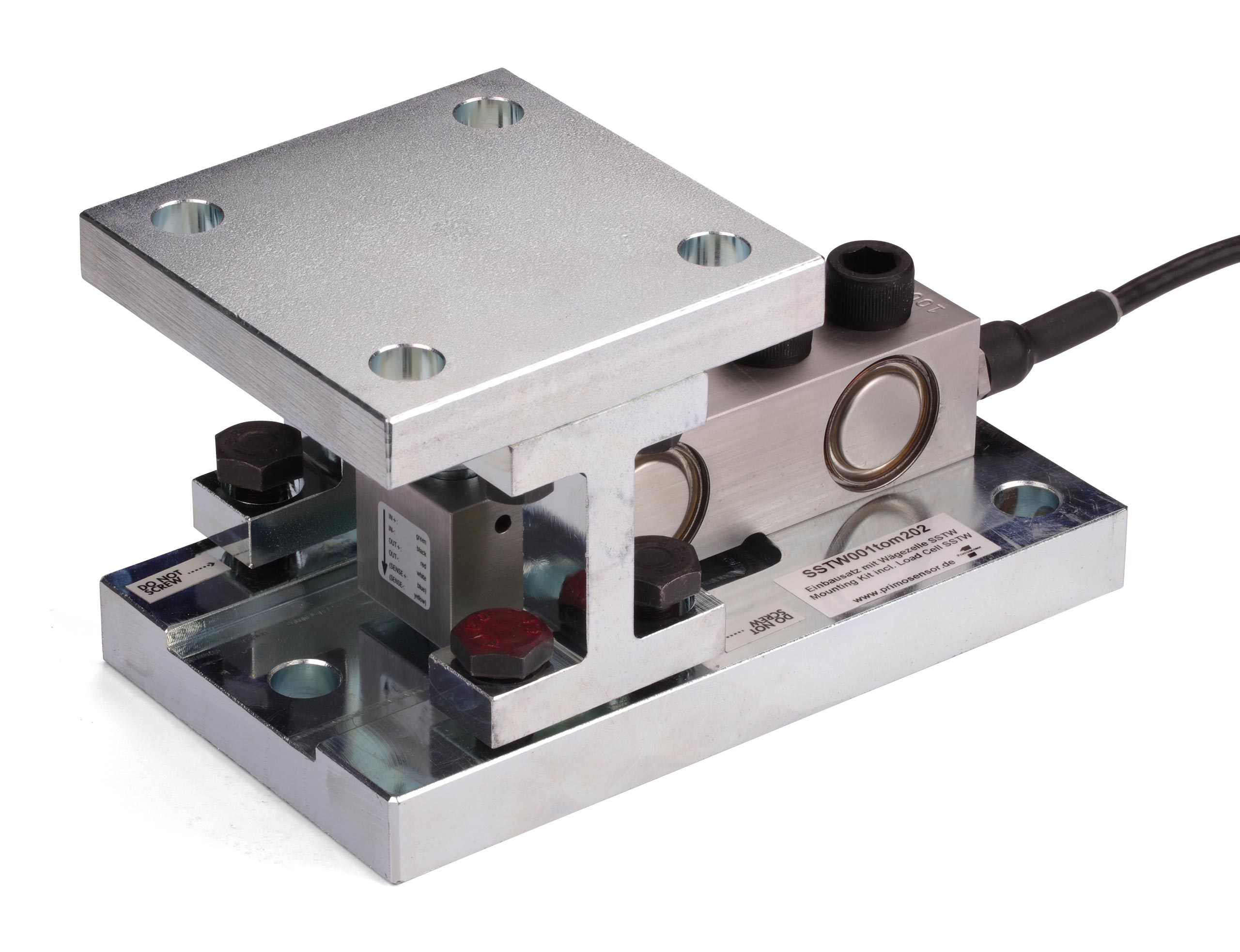

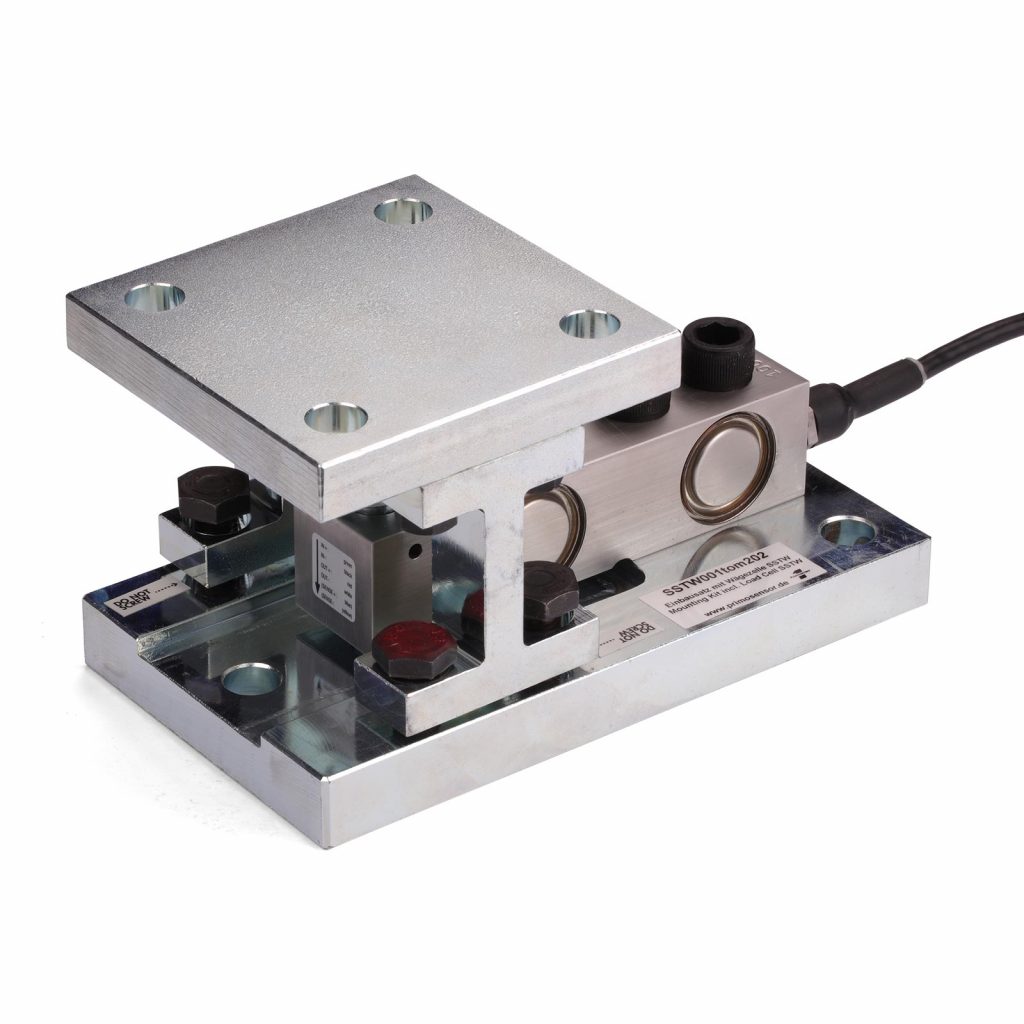

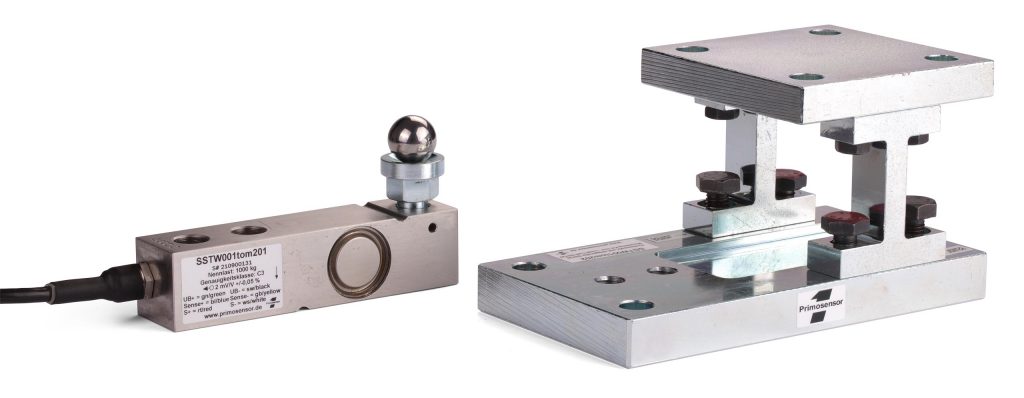

Bending and shear beam load cells and weighing modules

Bending and shear beam load cells are the most commonly used types of load cells in industrial weighing technology for weighing small to medium-sized containers and platforms, typically with 3 or 4 support points or feet. Bending beam load cells are used for the smaller load ranges. They are typically available with nominal loads from 5 kg to 500 kg.

Shear beam load cells are then used for the higher loads. They are stiffer than the bending beams and are typically available with rated loads from 300 kg to 10,000 kg. Both types are characterized by very high degrees of protection with IP68/69k and are made entirely of stainless steel. Appropriate installation kits enable easy assembly and quick assembly of a very well-functioning platform or container scale.

Bending beam

- Frequently used in the industry

- from 5 kg to 500 kg

- Accuracy <0,017 % F.S.

Bending beam force transducers or load cells are a widespread standard in industry. They are used to measure compressive forces or loads, especially in weighing applications in the small to medium load rang. The advantage of bending beam load cells ist the possibility of also measuring small loads with very high accuracy, while at the same time offering high IP protection and high robustness.

Shear beam

- Frequently used in the industry

- from 300 kg to 10,000 kg

- Accuracy <0,017 % F.S.

Shear beam force transducers or load cells are a common standard in the industry. They are used to measure compressive forces or loads, especially in weighing applications in the medium load range. The advantages of shear beam load cells are high accuracy, robustness and insensitivity to lateral forces.

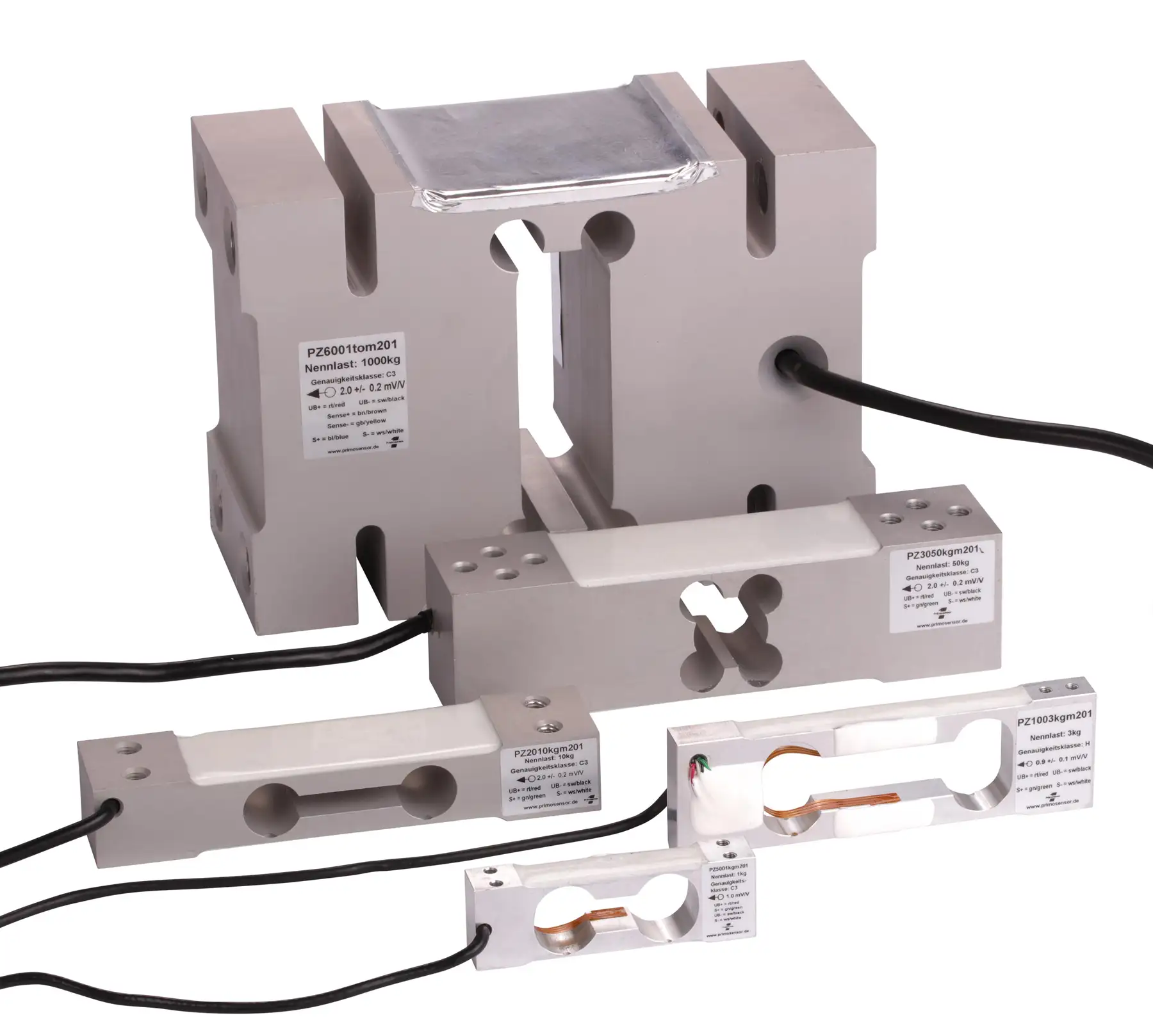

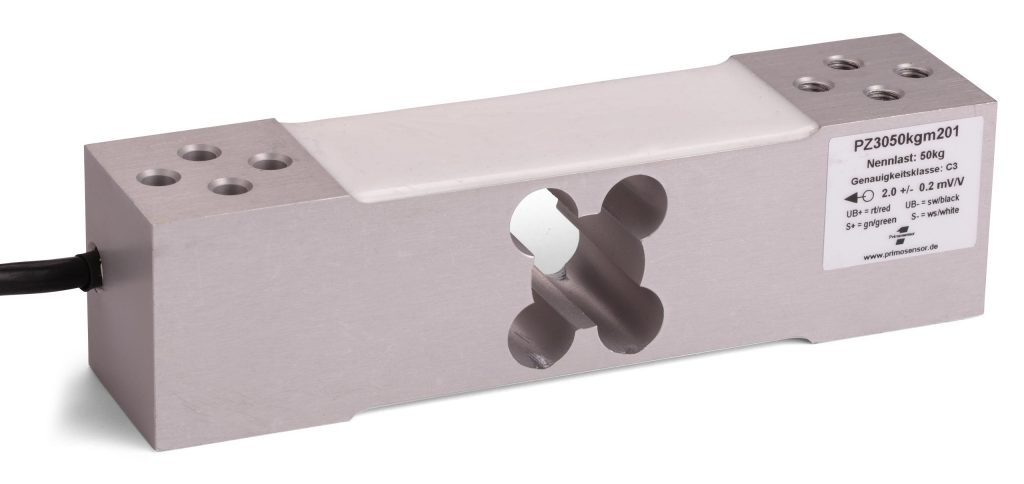

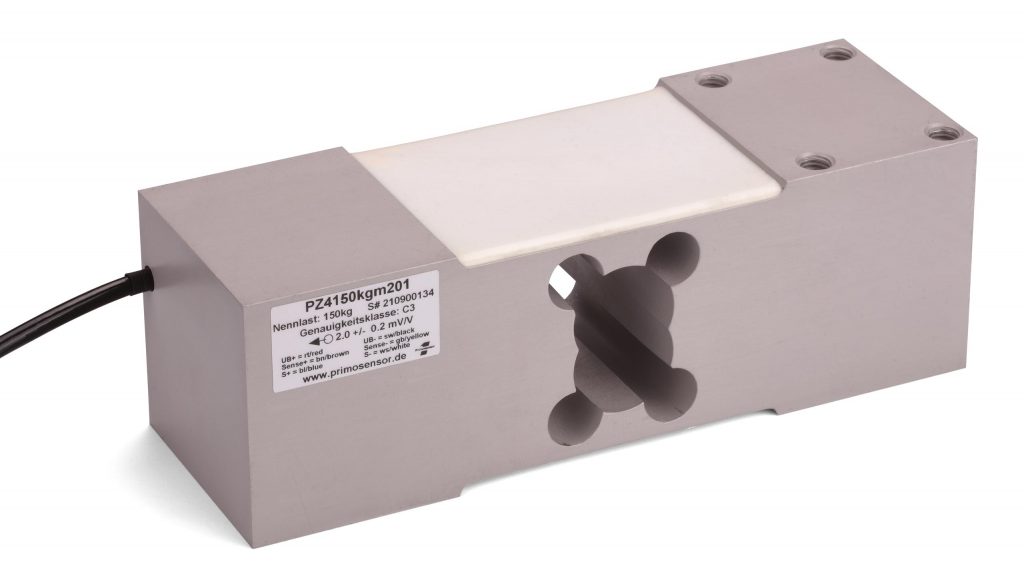

Primoforce® Single Point Load Cells

Single point load cells have a very special geometry. This allows platform scales to be constructed with only one load cell arranged centrally under the platform. Hence the name “single point load cell”. They are designed in the manner of a parallel link, which enables them to absorb bending and torsional moments caused by eccentric force application without having an unfavorable effect on the measurement result. Single point load cells are characterised by high accuracy and are available with nominal loads from 150 g to 2000 kg. They are usually made of aluminium, but can also be supplied in stainless steel with a high degree of protection. The recommended maximum possible platform size for the various versions is given in the corresponding data sheets.

Single Point Load Cell

110 x 33 x 10 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 300 g to 3,000 g

- Accuracy of <0.010 % f.s.

- Platform size: 200 x 200 mm

The PZ1 load cell is a high-precision single point load cell and was specially developed for use in small platform scales with correspondingly small loads. It is available with nominal loads from 300 g to 3000 g.

Single Point Load Cell

130 x 30 x 22 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 2.5 kg to 200 kg

- Accuracy <0,020 % F.S.

- Platform size: 250 x 350 mm

The PZ2 single point load cell has been specially developed for use in small to medium platform scales with correspondingly small and medium loads and offers high accuracy. The PZ2 load cell is available with nominal loads from 2.5 kg to 200 kg.

Downloads | Data sheet & STEP files

Single Point Load Cell

130 x 30 x 22 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 30 kg to 500 kg

- Accuracy <0,020 % F.S.

- Platform size: 400 x 400 mm

The PZ3 single point load cell has been specially developed for use in medium-sized platform scales with corresponding loads and offers high measuring accuracy. The load cell is available with nominal loads from 30 kg to 500 kg.

Single Point Load Cell

188 x 63.5 x 62.3 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 50 kg to 635 kg

- Accuracy <0,020 % F.S.

-

Platform size:

50 - 200kg: 600 x 600 mm;

250 – 635 kg: 600 x 800 mm

The PZ4 single point load cell has been specially developed for use in medium to large platform scales with corresponding loads and offers high measuring accuracy. The load cell is available with nominal loads from 50 kg to 635 kg.

Single Point Load Cell

70 x 22 x 16 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 300 g to 3,000 g

- Accuracy <0,020 % F.S.

- Platform size: 200 x 200 mm

The PZ5 single point load cell was specially developed for use in small platform scales with correspondingly small loads and offers high measuring accuracy. It is available with nominal loads from 300 g to 3000 g.

Single Point Load Cell

176 x 125 x 76 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 750 kg to 2,000 kg

- Accuracy <0,020 % F.S.

- Platform size: 1200 x 1200 mm

The PZ6 load cell is the largest single point load cell available and has been specially developed for use in large platform scales with correspondingly high loads and offers high measuring accuracy. It is available with nominal loads from 750 kg to 2000 kg.

Single Point Load Cell

130 x 30 x 30 mm

- Platform scales with only one load cell positioned centrally under the platform

- from 10 kg to 100 kg

- Accuracy <0,25 % v.E.

- Platform size: 200 x 200 mm

This platform force transducer with integrated amplifier electronics was specially developed for applications with eccentric force application or in small platform scales. The special geometry allows only one force transducer to be used under a platform. The sensor is mounted as centrally as possible.