We Find the Most Suitable Approach for Your Need

We Find the Most Suitable Approach for Your Need

Inventive. Customer-driven. Flexible.

When it comes to force measuring devices, we are the experts who will support you with innovative ideas and a high level of competence. We have the right product for your application, or we can adapt it to your individual circumstances. But we also pursue completely new approaches for entirely new solutions together with you.

Talk to us if your project involves load measurement or force measurement.

Independent from technologies

We operate independently of any technology. In other words, our end products are based on strain gauges. Depending on the quantity and desired accuracy, we offer the solution with the optimal price-performance ratio. Either force transducers that are implemented with bonded strain gauges or those that are built with thick-film or thin-film sensors.

We always strive for the best solution

Primosensor accurately designs its measurement systems, implements them constructively, and tests them in suitable load devices. This means you are ideally equipped to professionally and reliably measure forces – and also torques – in your machines and systems.

Special solutions, developed and realized for our customers

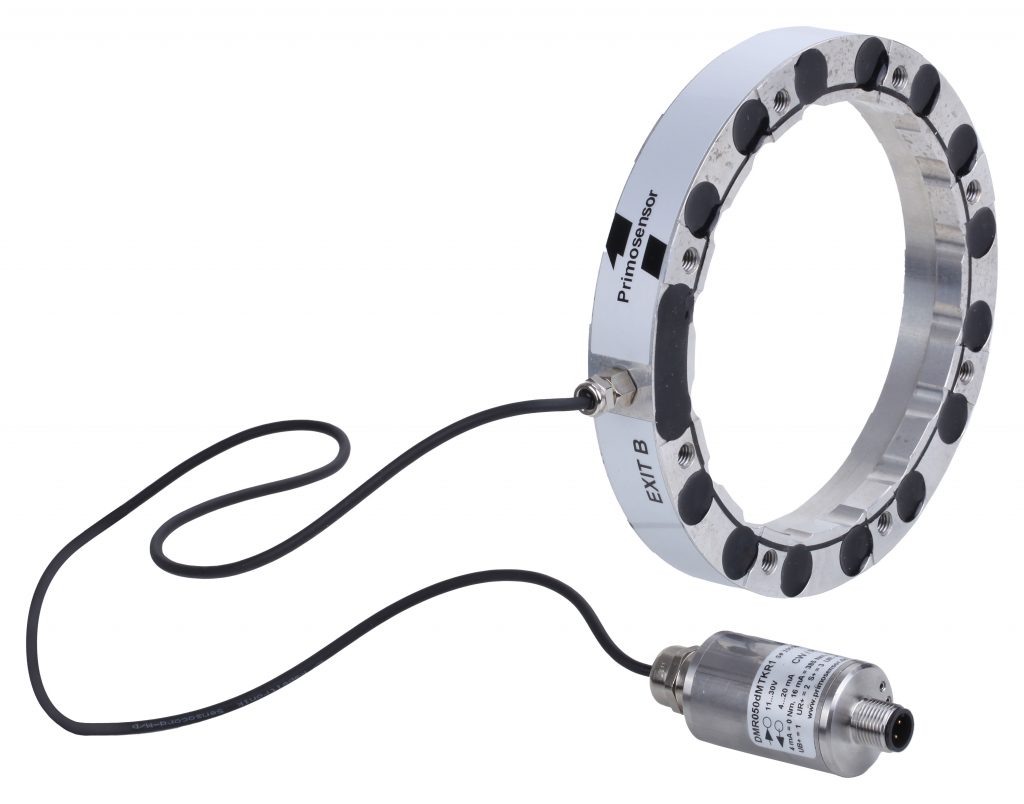

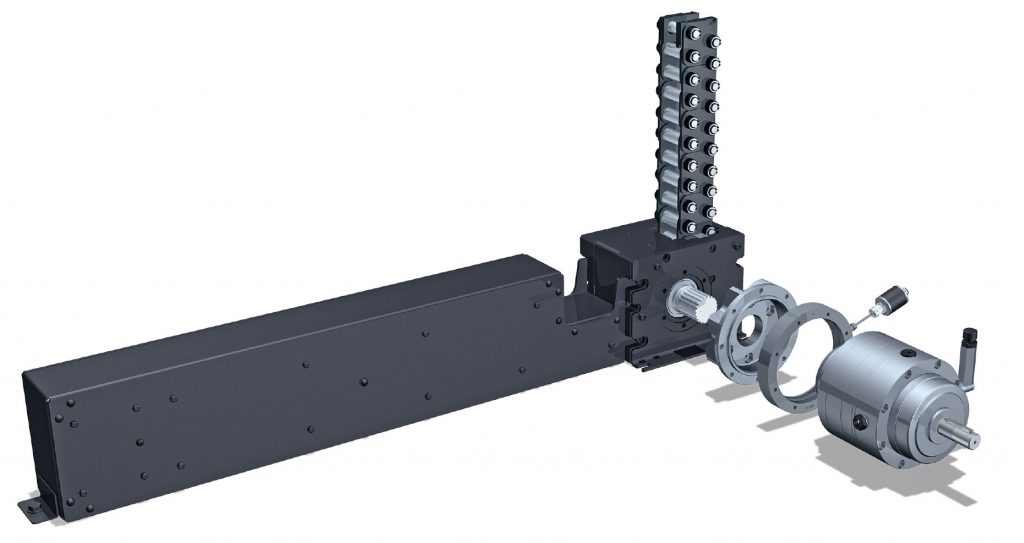

Torque measuring ring for podiums

In order to create a particularly flat event platform with overload detection, our long-standing customer Serapid needed a force sensor with a maximum installation height of 10 mm on the push chain. And we even found a solution for that! We designed a torque measuring ring that, when mounted between the gearbox and chassis, measures the reaction torque.

Additional height on the push chain: 0 mm!

Professional blood pressure monitor

Sensors are required for a non-invasive, highly accurate, professional blood pressure monitor. The device, placed on the wrist, should measure blood pressure in the veins. Since their position varies slightly from person to person, we developed a comb-shaped sensor structure that ensures that in every case a “prong” generates a usable signal. The sensor was implemented using thin-film technology.

Handrim sensor for electric wheelchair

Anyone converting a wheelchair into an electric wheelchair needs a force sensor for control in addition to the electric drive. Our solution consists of cubes that can be mounted between the gripping ring and the wheel rim using simple mounting parts. They are very sensitive in the direction of movement, but rather robust in all other directions, for example to withstand the supporting forces of heavy people without damage.

Thread tension sensor for weaving machine

A cost-effective sensor was sought to measure the thread tension on weaving machines. In our innovative sensor concept, all metallic sensor components are cut from sheet metal using a laser and then layered and connected to form the sensor structure. The deformation of a component under load is evaluated using the Hall effect and then converted into 0…10 V.

Forestay sensor

Measure the forces in the forestay or on the loaded sheets and thus trim the sails optimally. Not just once, but constantly, to keep the ship optimally upwind.

The wireless, battery-powered sensor sits in the forestay and sends its data to the on-board computer, which evaluates and displays it. The helmsman reads the power on the forestay on the display and, with a little feel, brings the boat perfectly into the wind.

Press-fit sensors

There are applications where, in order to perform a necessary measurement, an existing component cannot simply be replaced by a measuring component – a sensor. However, with the help of press-fit sensors, existing components can be “converted” into sensors.

We implement this in a system for recording the axle load of freight wagons: the existing rails are drilled through at a certain distance and fitted with press-in sensors.