Efficient force measurement technology

Strain Transducer and Press-fit Sensors

Strain transducers and press-fit sensors are essential tools for reliable measurements in force measurement technology. They enable the precise recording of deformations and forces in various materials and assemblies. – Request a project

Strain transducer (DA)

Strain transducers are bolted to steel structures such as machine frames or steel beams in order to record strains, compressions or shear stresses. These sensors are precisely positioned to provide accurate measurement data. Thanks to modern technology, the measured values can be easily integrated into various monitoring systems, enabling continuous monitoring of loads.

- is characterized by its compact and robust design

- three measuring ranges available

- digital output signal: CANopen

Press-fit sensors (EPS)

Press-fit sensors are inserted into special holes to measure the stresses in the component. Together with the component, the sensors are adjusted so that the zero point and sensitivity are correct. In addition to the condition without load, only one other defined load condition is required. Thanks to the built-in amplifier, the sensors supply either 0 to 10 V or 4 to 20 mA directly at the output.

- is characterized by its compact and robust design

- three measuring ranges available

- analog output signal: 4...20 mA

- digital output signal: CANopen

Strain transducers and press-fit sensors provide reliable data for demanding applications.

Whether in the structural monitoring of bridges, quality control in production lines or biomechanical analysis.

A low-cost alternative

Strain transducers and press-fit sensors can be a cost-effective alternative for measuring large forces. They measure in the “force shunt”. This refers to the indirect transmission of forces in a mechanical system via additional components or connections that influence the force distribution.

You decide!

Customer-specific adaptations for strain transducers and press-fit sensors are possible at any time.

Do you need an strain transducer or press-fit sensor adapted to your requirements? No problem! Whether shape or design, material or ports, analog or digital Output signals – our team will develop for you or together with you exactly the strain transducer or press-fit sensor you need for your project. This is because it has decades of experience and a great deal of expertise in the development of force measurement technology and the appropriate tools and machines to produce the prototypes you need

Your component becomes a force sensor

The idea of using an existing component as a force sensor opens up new possibilities for efficiency. Instead of integrating separate sensors, a component is functionally extended. This saves space, reduces costs and enables seamless integration into existing systems. This innovative method allows designs to be upgraded in a smart and resource-saving way.

Design requirements

Not every component is suitable for sensor integration – material, material thickness, elasticity and geometric properties are decisive. Adjustments are often necessary, such as modifying surfaces and weakening or reinforcing certain areas. These measures optimize force transmission and improve the accuracy of the sensor without impairing the original function of the component.

Assembly and calibration

The integration of sensors requires precision: strain gauges are precisely positioned and firmly attached. Calibration is then carried out to adapt the sensor to the intended force range. This ensures that the measured values are reliable and precise, regardless of the type of load or operating environment.

Application examples

An illustrative example is the use of screws or bolts as force sensors in the mechanical engineering industry. Chassis components can also measure forces in the automotive industry. In medical technology, sensors for prostheses or implants can be used to monitor loads. The versatility of this solution makes it attractive for numerous industries.

Aerospace

In aircraft, wings or turbine housings can be equipped with sensors to monitor structural loads caused by air currents. This improves safety, enables precise maintenance and extends the service life of components.

Renewable energies

Rotor blades or foundation components of wind turbines can serve as force sensors to measure wind loads or structural stresses in real time. This data helps to optimize operation and ensure the long-term stability of the system.

Building industry

Load-bearing elements of buildings or bridges can be used as sensors to monitor load distributions. This enables early detection of material fatigue and helps to ensure the safety of infrastructures even under changing conditions.

Robotics

Gripper arms in robots can use integrated force sensors to precisely measure the force exerted. This enables them to handle sensitive workpieces safely and ensure greater precision and flexibility in complex production processes.

Sports technology

Sensors integrated into bicycles, skis or running shoes record forces in order to analyze movement sequences and loads. This information helps athletes to improve their technique and minimize the risk of injury.

Medical prostheses

Prostheses with force sensors provide users with feedback on loads and pressure. This improves control and makes the prosthesis more intuitive to use, which significantly improves quality of life and supports rehabilitation.

Surgical instruments

Force sensors in minimally invasive instruments allow surgeons to precisely control the forces applied. This minimizes tissue damage and increases the accuracy of procedures, leading to better results.

Transportation systems

Sensors in truck or train axles monitor the load in real time. This ensures optimized weight distribution, prevents overloading and increases efficiency and safety in the transport sector.

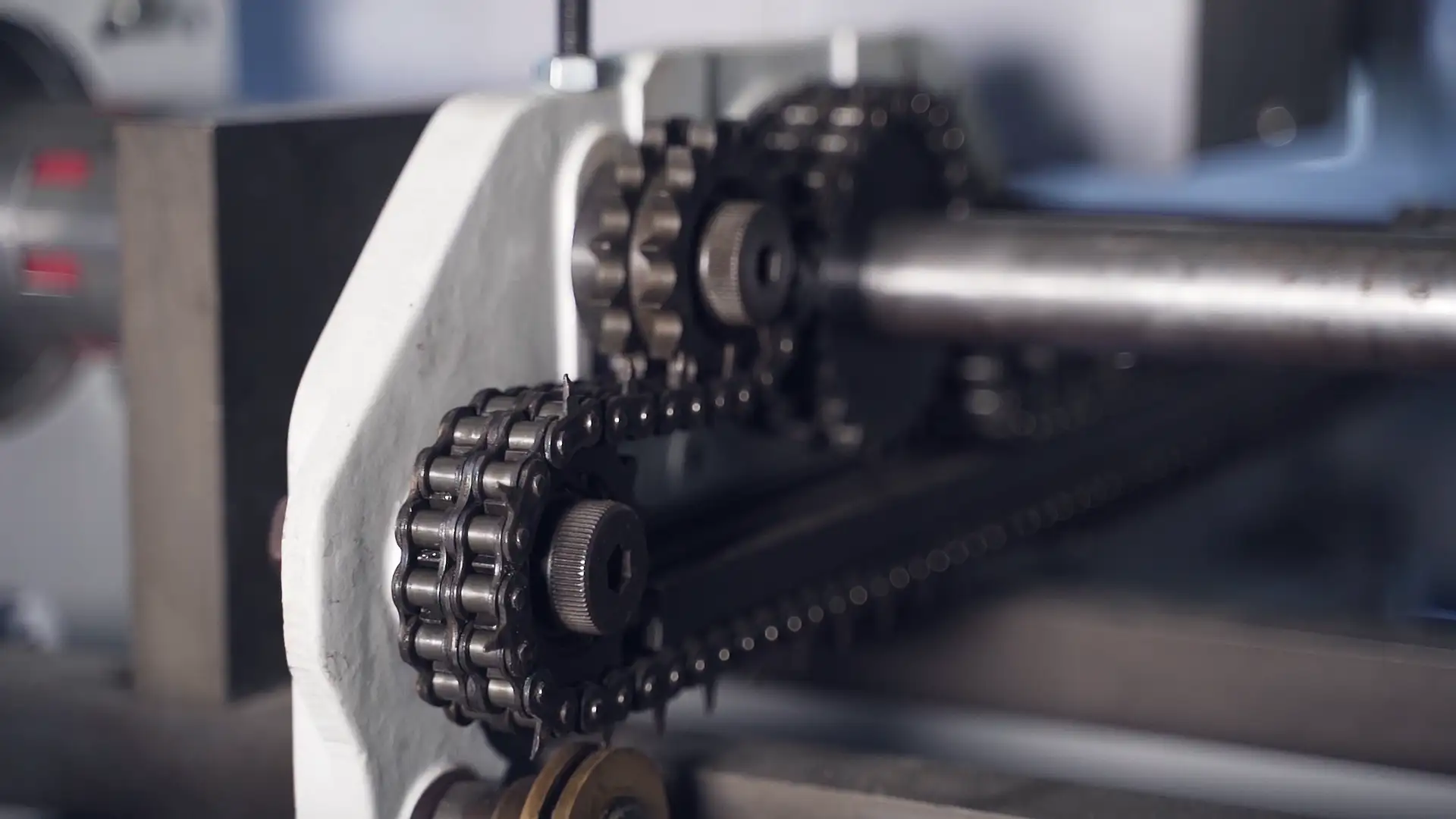

Conveyor technology

Force sensors used in conveyor belts detect overloads and wear at an early stage. This reduces unplanned downtime, optimizes maintenance and extends the service life of conveyor systems in industrial applications.

Smart Cities

Force sensors in light poles, bridges or park benches record loads caused by wind, weather or users. This data helps to increase the service life of infrastructure and integrated IoT solutions enable predictive maintenance in urban areas.

Internet of Things (IoT)

Force sensors are networked with IoT platforms to intelligently evaluate measurement data. This creates new opportunities for Industry 4.0 applications, such as monitoring production processes or optimizing machine maintenance in real time.

Advantages of the conversion

The transformation of a component into a force sensor enables the efficient use of existing resources. This significantly reduces overall costs and space requirements. In addition, real-time force measurement enables more precise diagnostics and control. These advantages make the method not only economically attractive, but also future-proof for smart designs.