Force transducers and torque sensors for

Storage and retrieval machines

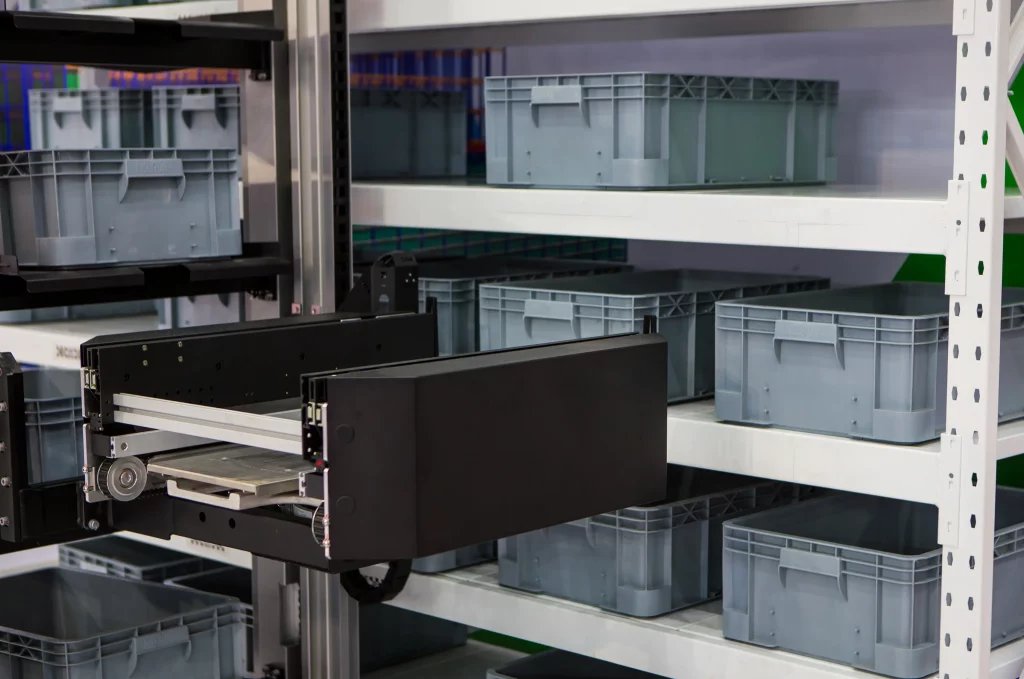

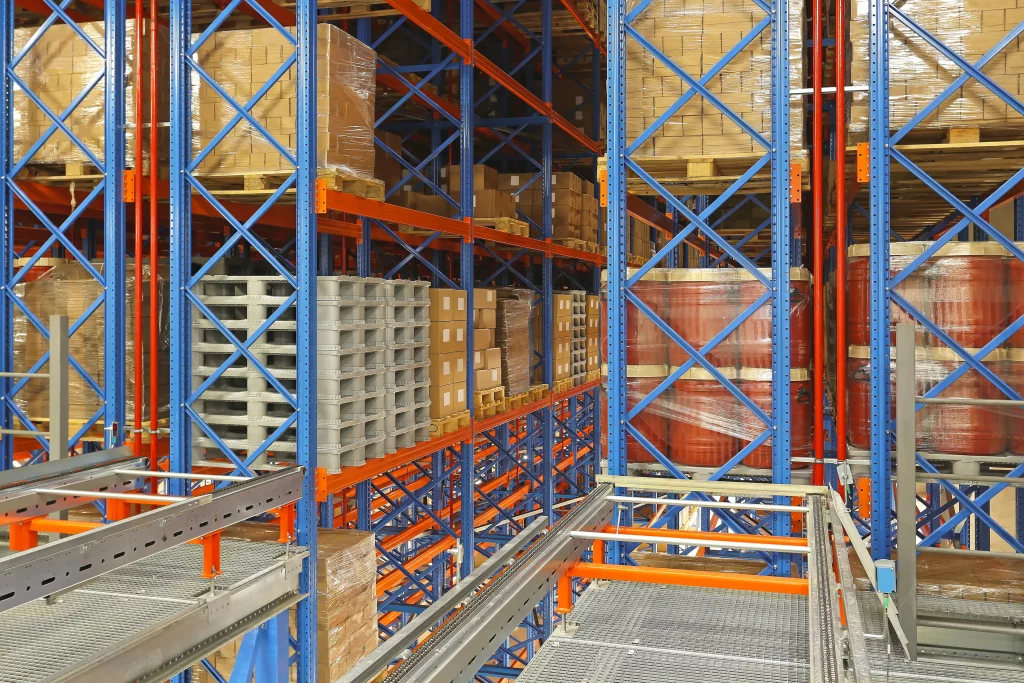

Storage and retrieval machines (SRMs) are central components of automated warehouse technology. They are used to store and retrieve load units—such as pallets, containers, or crates—in high-bay warehouses. Their precise and rapid movement along rows of shelves enables efficient use of space and high throughput. Modern RAS are often partially or fully automated and integrated into higher-level warehouse management systems.

Intelligent sensor technology for maximum operational reliability and efficiency

To ensure the operational safety, reliability and efficiency of such systems, force transducers and torque sensors are increasingly being used in storage and retrieval machines. Very often in combination with evaluation electronics such as our DGS4116 digital limit value switch or our DVST1PN digital measuring amplifier for simple bus connection to ProfiNet systems. The DVST1 is available with the following bus interfaces: RS-485 / ProfiBus DP / CANopen / Ethernet / EthernetIP / DeviceNet / EtherCat.

Together with our evaluation devices, these sensors perform important monitoring and control tasks during operation.

Tasks and areas of application for force and torque sensors

Monitoring load acceptance and delivery

When storing and retrieving goods, force sensors measure the forces acting on grippers, lifting forks, or load-bearing devices. This makes it possible to detect whether a load has been picked up correctly, whether there are overload situations, or whether obstacles are interfering with the movement sequence.

Protection against overload and mechanical damage

Continuous measurement of forces and moments allows unacceptable loads to be detected at an early stage. If a limit load is exceeded, the system can automatically stop operation or issue a warning message. This protects both the structural components of the RBG and the stored goods.

Condition monitoring and predictive maintenance

Deviations in the measured forces or torques can indicate wear, misalignments, or incipient damage to mechanical components. Continuous data acquisition and analysis enable condition-based maintenance intervals to be planned (predictive maintenance), which reduces downtime.

Optimization of motion control

Torque sensors on drive axles or cable/belt drives enable precise control of drive forces. This allows motion sequences to be made smoother, more energy-efficient, and more dynamic. This contributes to process reliability, especially in the case of high accelerations or sensitive goods.

Safety features and collision avoidance

If atypical forces or moments are registered during the driving or lifting process, the system can trigger an immediate emergency shutdown or an automatic corrective movement. In this way, the sensors increase operational safety and protect people and materials.

In short...

… The use of force transducers, torque sensors, and evaluation electronics in storage and retrieval machines is an essential component of modern warehouse technology. They enable the precise measurement of mechanical loads, contribute to process optimization, and ensure the reliable, safe operation of the systems. The integration of these sensors not only makes storage and retrieval machines more robust and durable, but also more intelligent—an important step toward networked and self-monitoring intralogistics systems in line with Industry 4.0.