Thick Film Technology

All over the world, force transducers are usually produced with glued strain gauges. We at Primosensor always doublecheck whether the customer’s requirements can be fulfilled better by using thin or thick film technology.

Steel instead of ceramics: thick film technology for force measuring

Thick film technology is not commonly used for force measuring purposes – without any reason! Ever since steel instead of ceramics is used for spring bodies, robust and durable force sensors can be produced very efficiently by means of this technology. Thick film technology is mainly used to produce pressure sensors and hybrid circuits. Our approach to use it for producing force sensors is entirely new.

Stainless steel for optimal spring characteristics

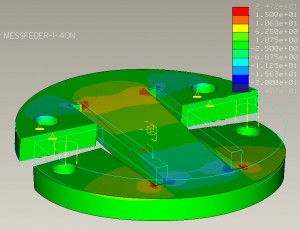

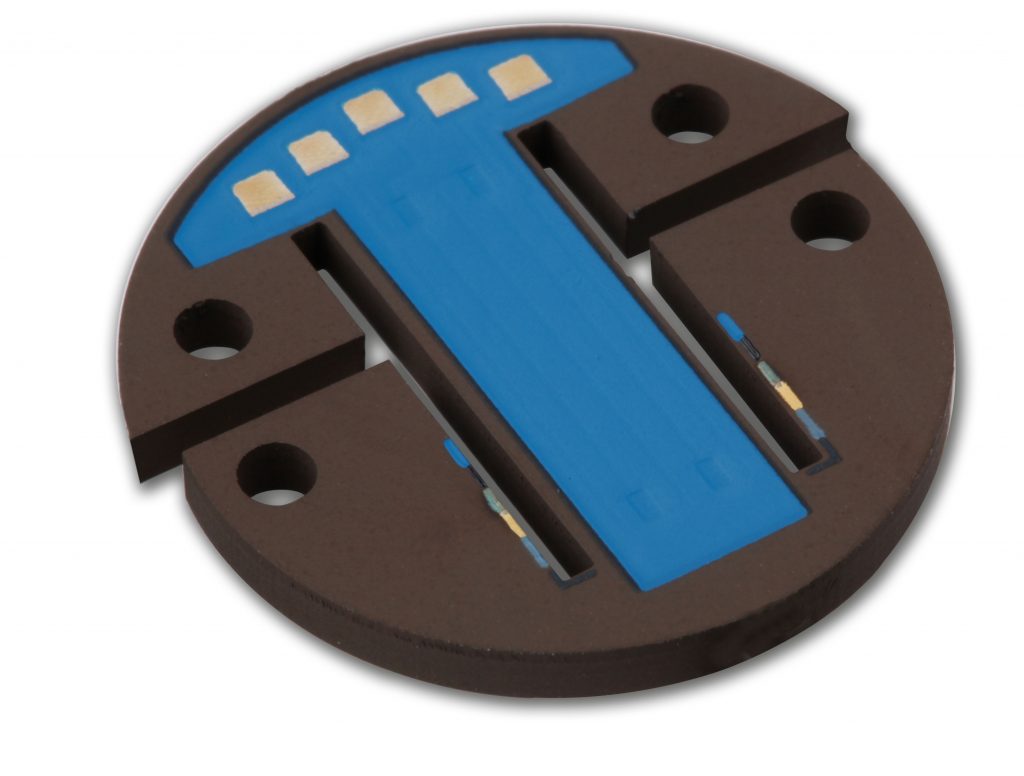

Instead of ceramics, we use stainless steel as carrier material for the thick film construction of our force transducers. This allows us to keep the spring characteristics and overload strength, which are typical for force transducers. In a multilevel process, insulating, resistance and contact layers are screen printed by coating with the respective pastes and sintered at approx. 850°C. A passivation layer protects the sensor from environmental impact.

Durable force sensors for small loads which do not need much space can be produced cost-effectively. The sensors are composited onto a single sheet and separated later. With an electrical resistance of 10 kΩ, the Wheatstone bridge is very energy-efficient and therefore ideal for battery-powered operation. A gauge factor of 6 to 8 enables transducers to be either resistant to overloads or low-noise. Integrating a preamplifier on the sensor surface turns the force transducer into a hybrid sensor with an extremely compact design.